Current electronic and hydraulic power steering systems cut turning effort significantly, provide a better road feel, and provide superior steering control.

Early steering systems were made up of rudimentary mechanical devices. Power steering is significantly more complicated nowadays. Without power steering, almost any vehicle would’ve been difficult to manage, from the classic mid-century behemoths to today’s lighter, denser front-wheel-drive vehicles, SUVs, and crossovers.

Hydraulic power steering dominated the highways for more than a half-century. That is no longer the case. Power steering systems that are both hybrid electro-hydraulic and entirely electric are becoming commonplace. Such technologies can even change the steering system’s help, depending on the situation.

What are the Differences Between the 3 Power Steering Mechanisms?

The 3 power steering technologies all provide the same critical purpose, although they do so in various ways. An electro-hydraulic system employs an electric motor to pump fluid, while a hydraulic system uses mechanically driven high-pressure fluid.

An electric system uses sensors and an electric motor. The ultimate result will be the same: you can spin the steering wheel effortlessly in any situation. Fully electric power steering devices save around one mile per gallon of fuel, need less upkeep, and are more reliable than hydraulic systems.

Hydraulic Power Steering

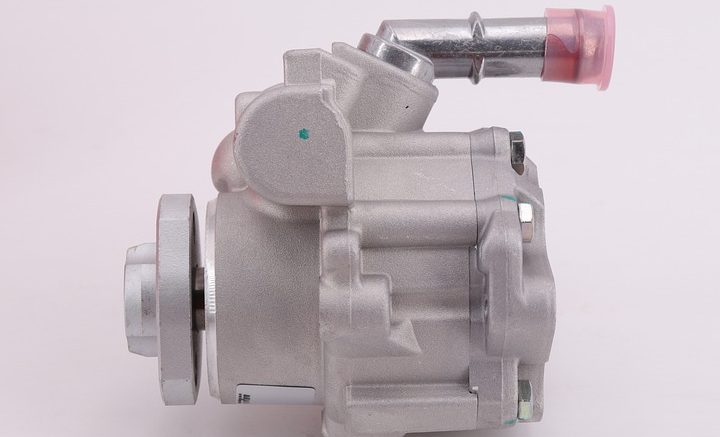

This system reduces steering efforts by using pressurized power steering liquid provided by the power steering pumps. An engine-driven auxiliary drive or conveyor belt activates the pump and sends high-pressure power steering liquid to the intake side of the power steering gear-control valves through the high-pressure line.

When moving the front tires, high pressure flowing on the control valve aids the driver. A reservoir holds the power steering fluid. Whenever the fluid comes from the steering gear at a significantly lower pressure, the reservoir’s fluid level is preserved.

Hydraulic power steering systems continually pump liquid and are affected by engine speed – high rotations per minute equal high-pressure generation, whereas low rotations per minute equal low-pressure generation. To ensure constant pressure, a power steering pump has a bypass valve that operates regardless of engine speed.

A good example of a hydraulic pump is the BMW e46 power steering pump.

Electro-Hydraulic Power Steering

Rather than an engine-driven accessory drive or conveyor belt, these systems use a brushless electric motor to drive the hydraulic power steering unit. This technology performs and feels the same as a traditional hydraulic power steering system.

Electric Power Steering

This technology does away with pressurized fluid and hydraulics. When the driver cranks the steering wheel, the front wheels are turned by a brushless bi-directional fixed magnet motor linked to the steering column or steering gear. Sensors determine which way the steering wheel is turned in order to help the steering gear is moving in the right direction.

Power steering, regardless of system type, only operates on the steering gear when the driver rotates the wheel.

Look for variable and variable-ratio electric power steer to maximize driver reaction and vehicle handling as more electronics are introduced to automobiles. Fly-by-wire steering, which uses a computer and sensors to remove the mechanical link between the steering gear and steering wheel, as well as self-driving cars that travel without driver input, will reshape automotive design and function.

Be the first to comment on "Different Types of Power Steering Pumps"