Industrial automation is a transformative technology that has revolutionized the manufacturing and production processes across various industries. From automotive assembly lines and food processing plants to pharmaceutical manufacturing facilities and logistics warehouses, automation systems play a pivotal role in enhancing efficiency, productivity, and quality while reducing costs and minimizing human intervention. In this article, we’ll delve into the world of industrial automation, exploring its key components, applications, benefits, and the future trends shaping the landscape of modern manufacturing.

At its core, industrial automation perth refers to the use of control systems, sensors, robotics, and advanced technologies to automate manufacturing and production processes. This includes the automation of repetitive tasks, such as material handling, assembly, packaging, and quality control, as well as the integration of data-driven technologies such as artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) to optimize operations and enable predictive maintenance and decision-making.

One of the primary components of industrial automation is programmable logic controllers (PLCs), which serve as the brain of automated systems, controlling and coordinating the operation of machinery, equipment, and processes. PLCs are programmed using specialized software to execute logic-based instructions, monitor sensors and input devices, and regulate actuators and output devices to perform specific tasks according to predefined parameters and sequences.

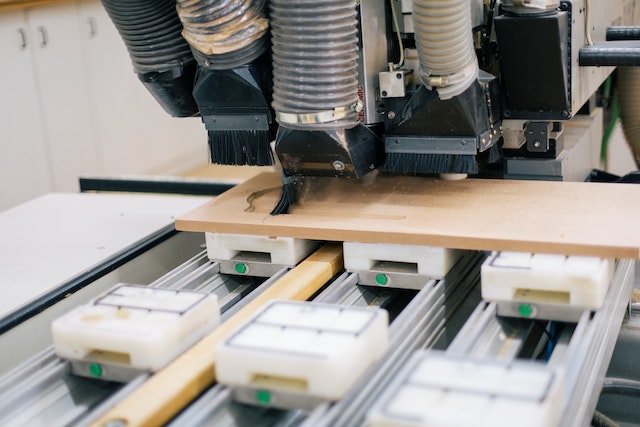

Another key component of industrial automation is robotics, which encompasses the use of robotic arms, manipulators, and automated guided vehicles (AGVs) to perform a wide range of tasks in manufacturing and logistics operations. Industrial robots are equipped with sensors, cameras, and end-of-arm tools to handle materials, perform assembly tasks, weld components, and palletize products with precision and efficiency. Collaborative robots, or cobots, are also gaining popularity for their ability to work alongside human operators in shared workspaces, enhancing productivity and safety.

Industrial automation has a wide range of applications across industries, including automotive manufacturing, electronics assembly, aerospace production, food and beverage processing, pharmaceuticals, and logistics and warehousing. In automotive manufacturing, for example, robots are used for welding, painting, and assembly tasks, enabling high-speed production and consistent quality control. In food processing plants, automation systems streamline packaging, labelling, and sorting processes, improving efficiency and hygiene compliance.

The benefits of industrial automation are manifold, ranging from increased productivity and efficiency to improved quality control, safety, and cost savings. By automating repetitive tasks and optimizing production workflows, industrial automation systems can significantly increase output and throughput while reducing cycle times and minimizing errors and defects. This leads to higher levels of product consistency and quality, which are essential for maintaining customer satisfaction and competitiveness in today’s global marketplace.

Furthermore, industrial automation enables manufacturers to achieve greater flexibility and agility in responding to changing market demands and production requirements. With the ability to reprogram and reconfigure automation systems on the fly, manufacturers can quickly adapt to new product designs, variations, and batch sizes without lengthy retooling or downtime. This flexibility allows for shorter lead times, faster time-to-market, and improved responsiveness to customer needs and preferences.

Safety is another critical aspect of industrial automation, as automation systems can help reduce the risk of workplace accidents and injuries associated with manual labour and hazardous tasks. By automating repetitive and dangerous tasks, such as heavy lifting, welding, and material handling, industrial robots and automation equipment can create safer working environments for employees while improving overall occupational health and safety standards.